Description

The ice storage systems used today were developed with the aim of making a large cooling capacity available within a few hours – and without having to use a lot of power in order to do this. The systems are based on the principle that the latent heat

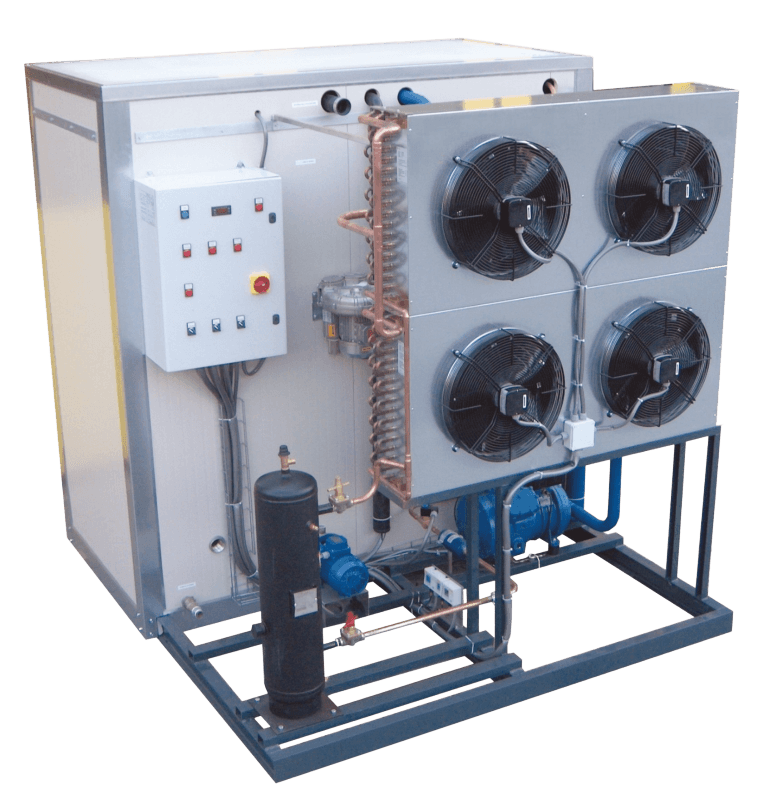

of fusion of 1 kg of ice at a constant melting temperature of 0 °C is 80 calories. This makes it possible to collect a large amount of cooling capacity in relatively small volumes. Our water chillers apply this principle: a perfectly insulated tank contains water into which smooth tube serpentine coils with a circulating refrigerant are immersed.

A layer of ice with a predetermined thickness forms on the outside of the coils, whereby this process is regulated by an ice thickness controller. Water is subsequently drawn from the tank at a temperature of 0.5 °C (ice melting is enabled by a stirring/

blower system) and sent to consumers using a pump, after which it is sent back into the tank and distributed over the coils.

The system is used for product areas wine, beer, fruit juice and distillates.

Features

- Water temperature (outlet): 0.5 °C

- Stainless steel centrifugal pump (glycol-resistant)

- Tank inside made of stainless steel 1.4301 (304)

- Tubular evaporator made of stainless steel 1.4301 (304) with d=21.3 mm

- Tank insulation made of PU foam 85 mm (side walls) and 100 mm (base)

- External cladding and cover made of insulated panels (sandwich) – galvanized steel + paint finish

- External cladding base/angle profiles: Galvanized sheet steel